Learn more about Hyliion and the KARNO technology.

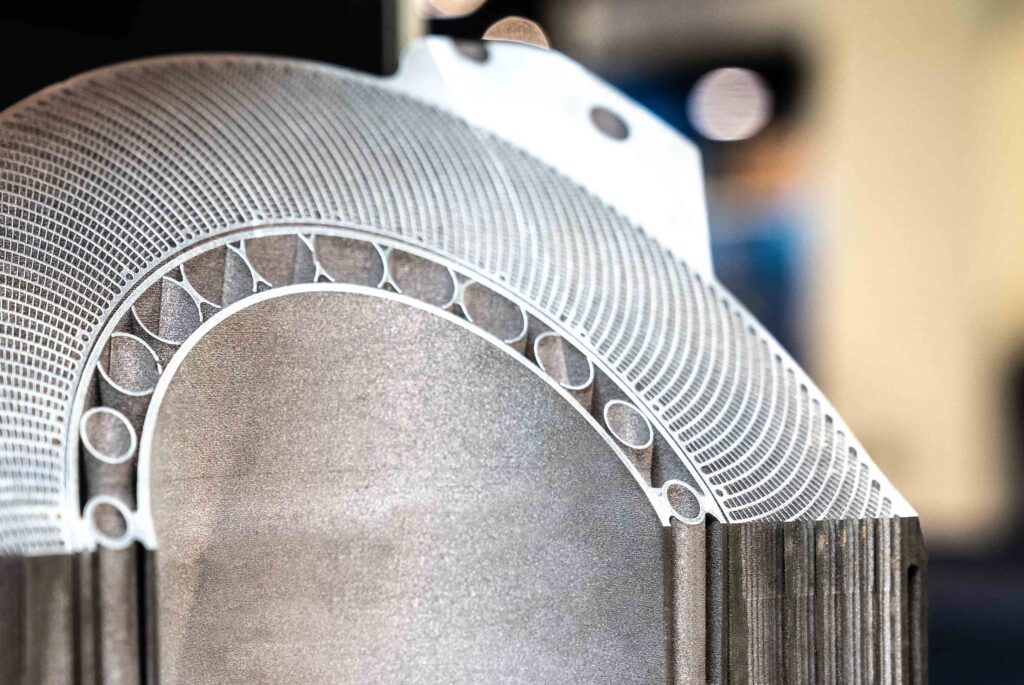

KARNO Tech Series: 9. Printed Parts

In this video, Hyliion’s Senior Director of Mechanical Engineering, Mike Notarnicola, takes us through the decision-making process behind choosing additive manufacturing for critical components of the #KARNO generator. Mike explains the advantages of using cobalt-chromium in metal 3D printing, including its strength, durability, and suitability for high-temperature environments. Discover how these choices enhance the performance and reliability of our technology, and learn why additive manufacturing plays a crucial role in pushing the boundaries of what’s possible in clean energy solutions.

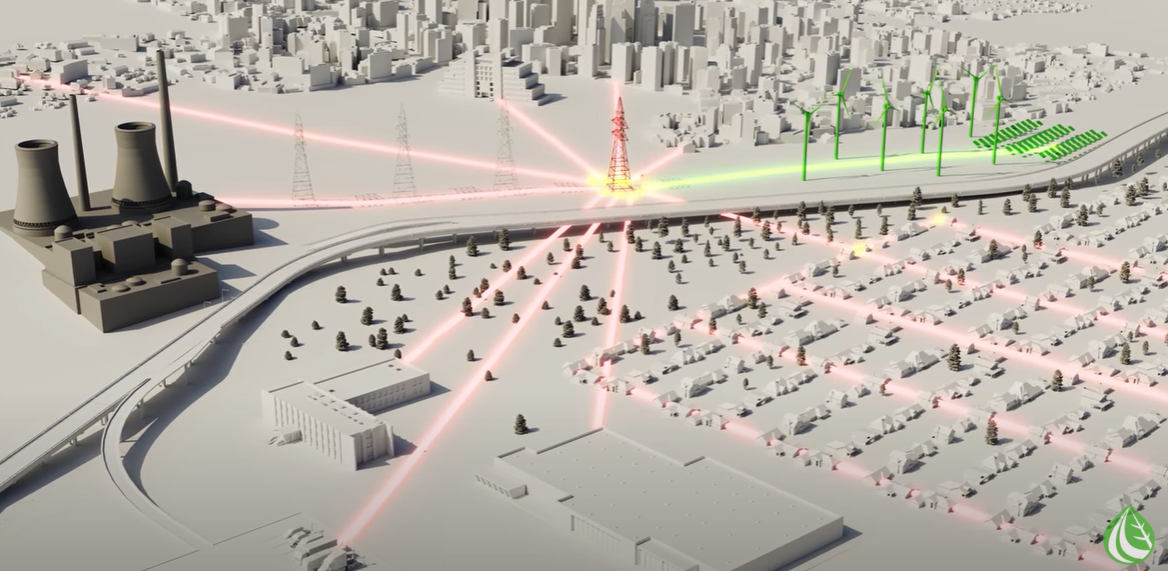

Rethink Power Generation

Experience the future of power with Hyliion’s KARNO™ Power Module. This revolutionary linear generator technology delivers high efficiency, fuel flexibility, and ultra-low emissions—providing reliable, scalable, on-demand energy. KARNO is redefining...

Industry Voices and Insights on the KARNO™ Power Module

Hyliion recently welcomed industry leaders to our Milford facility for an up-close look at the KARNO™ technology in development. They experienced firsthand the innovation behind the KARNO Power Module and...