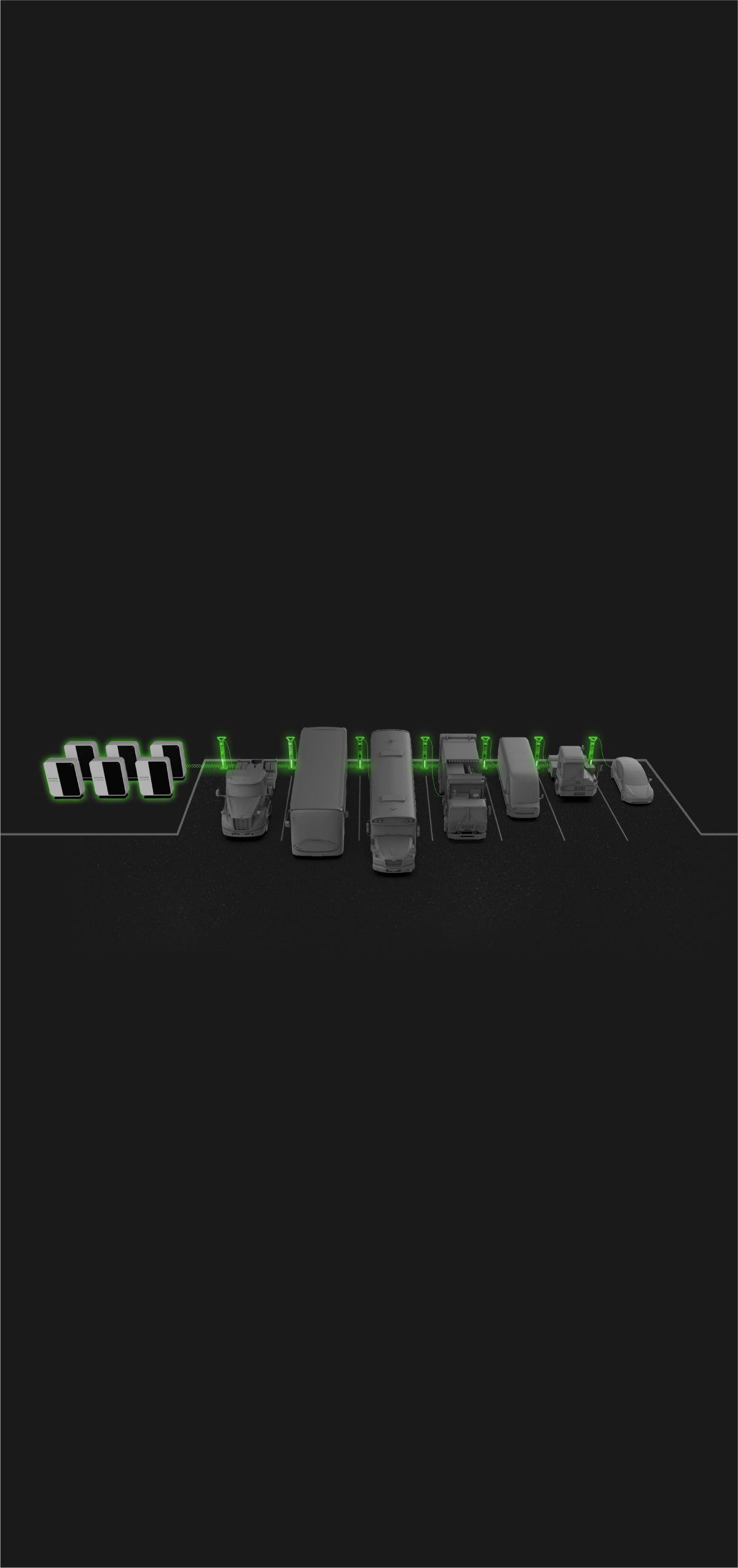

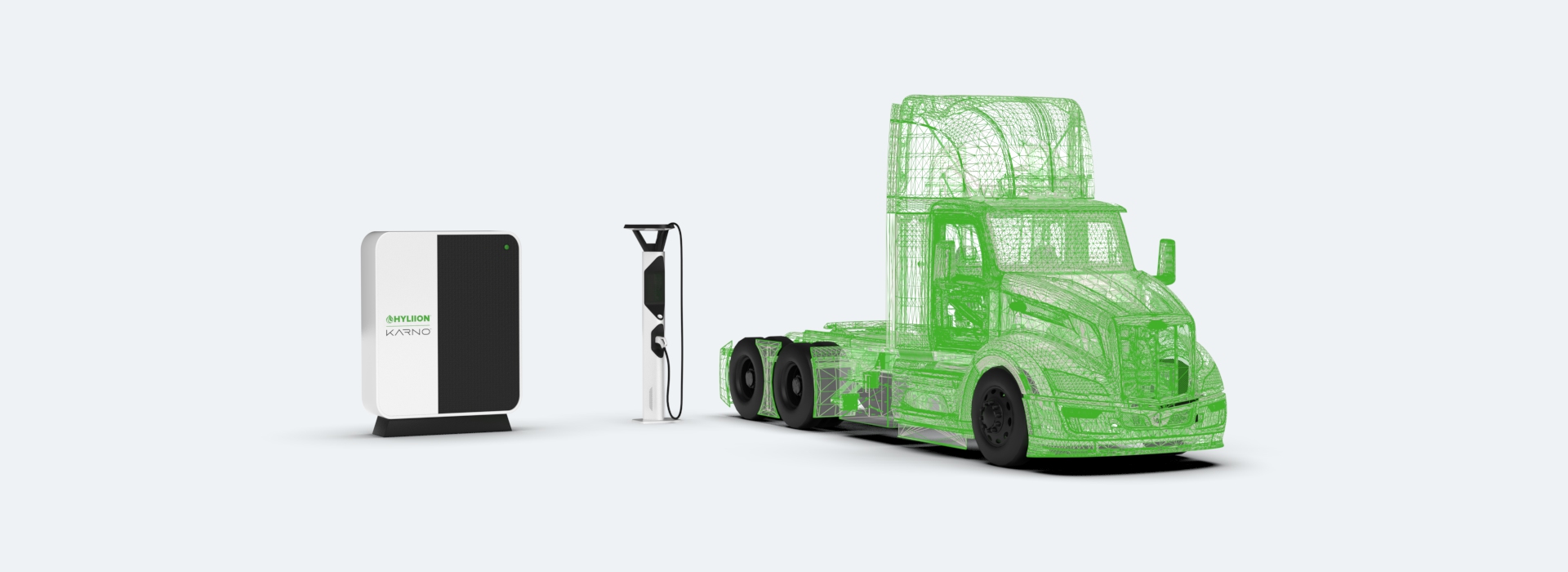

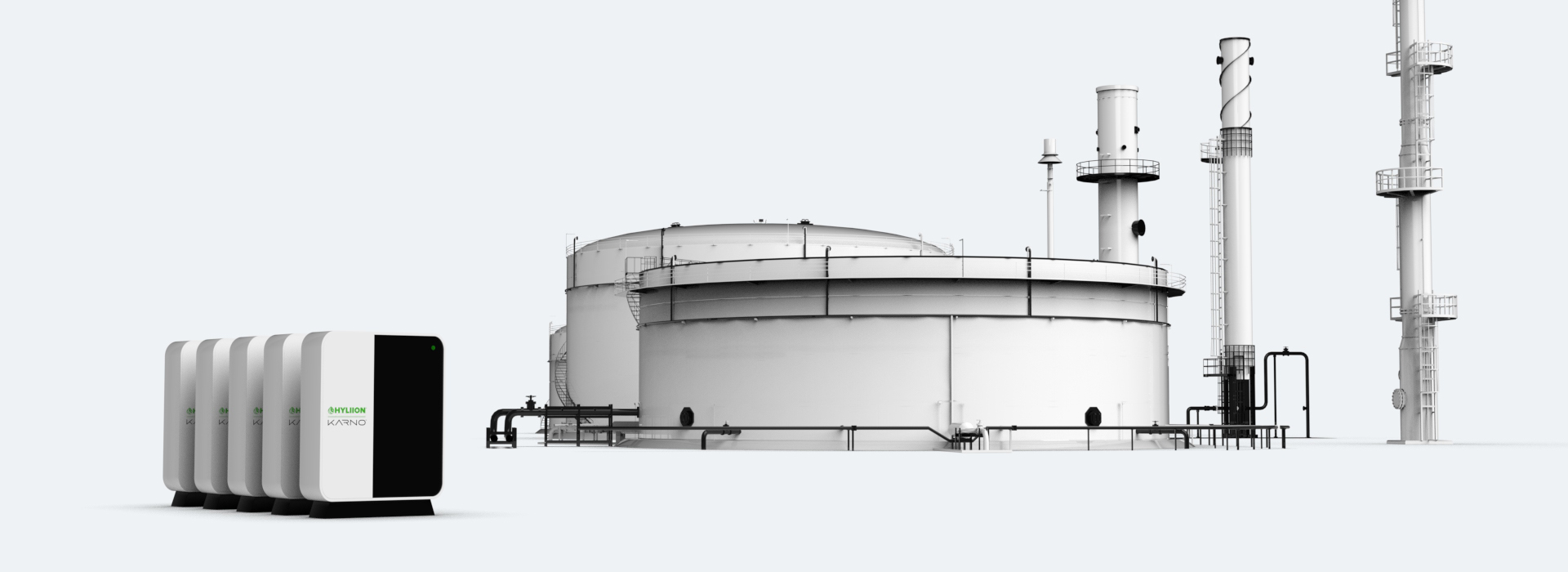

Whether it is integrated into a mobile platform, or in a stationary application, the KARNO generator provides unrivaled flexibility and performance.

KARNO™

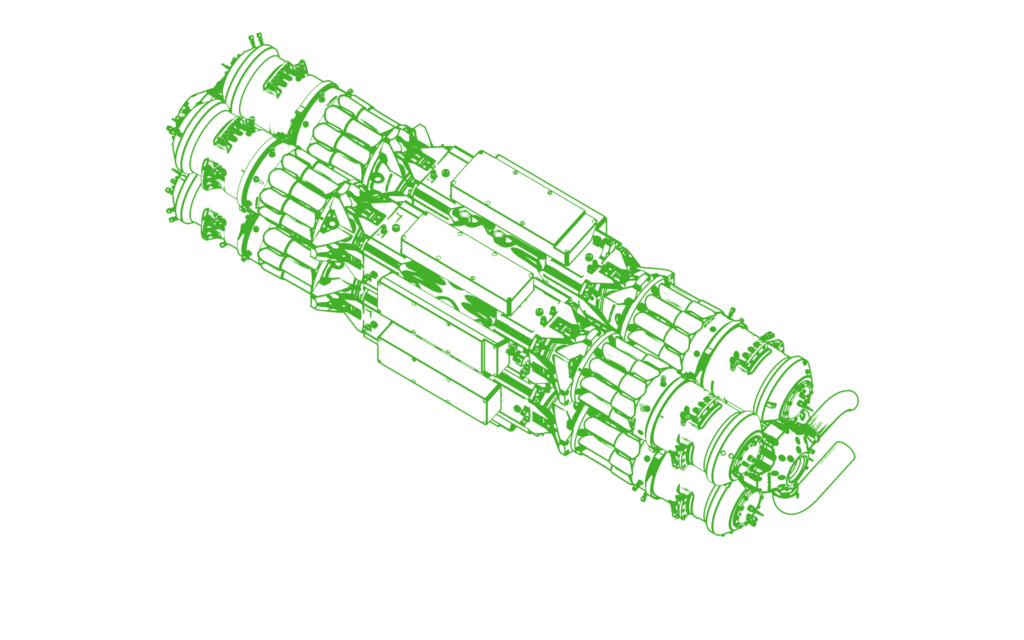

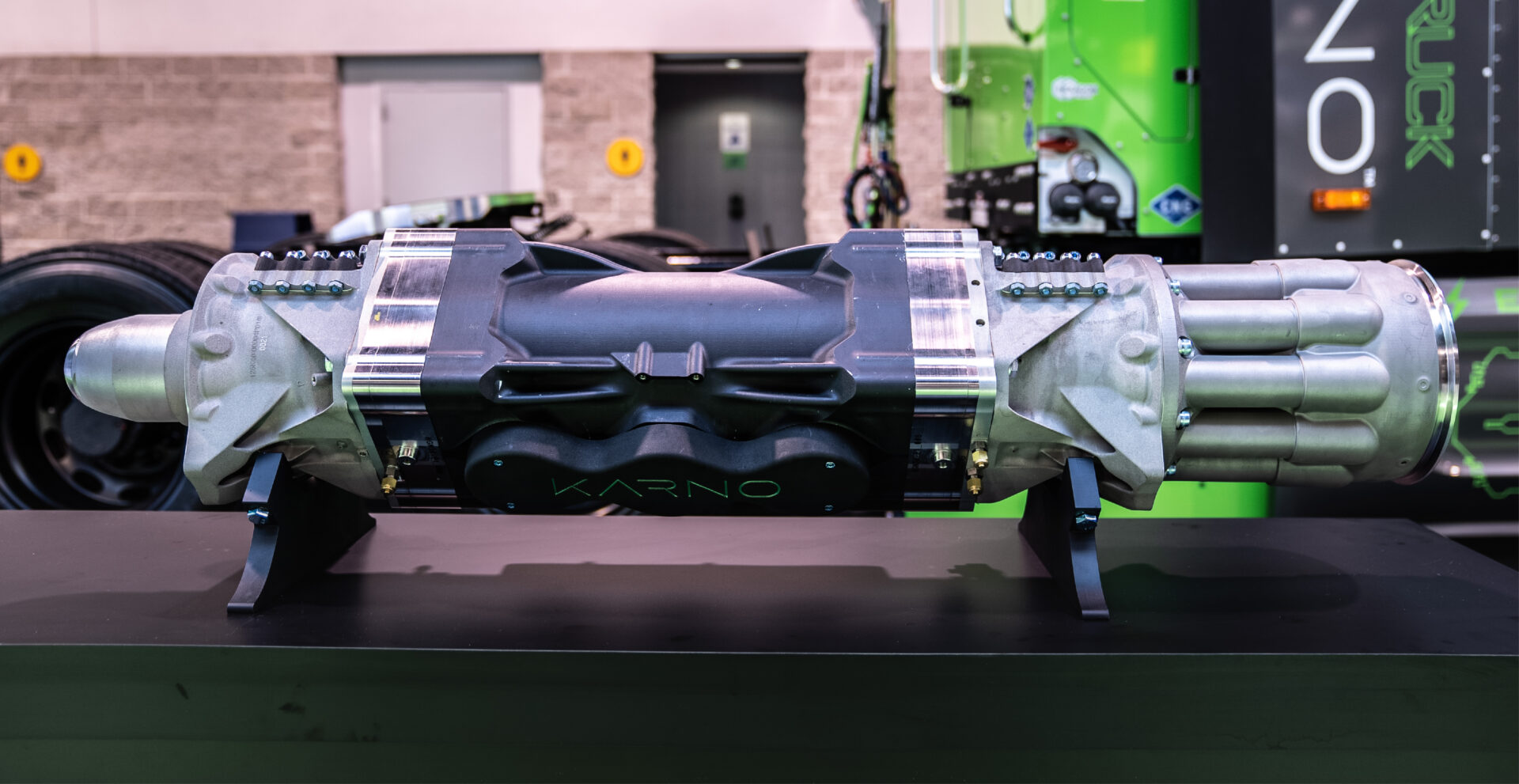

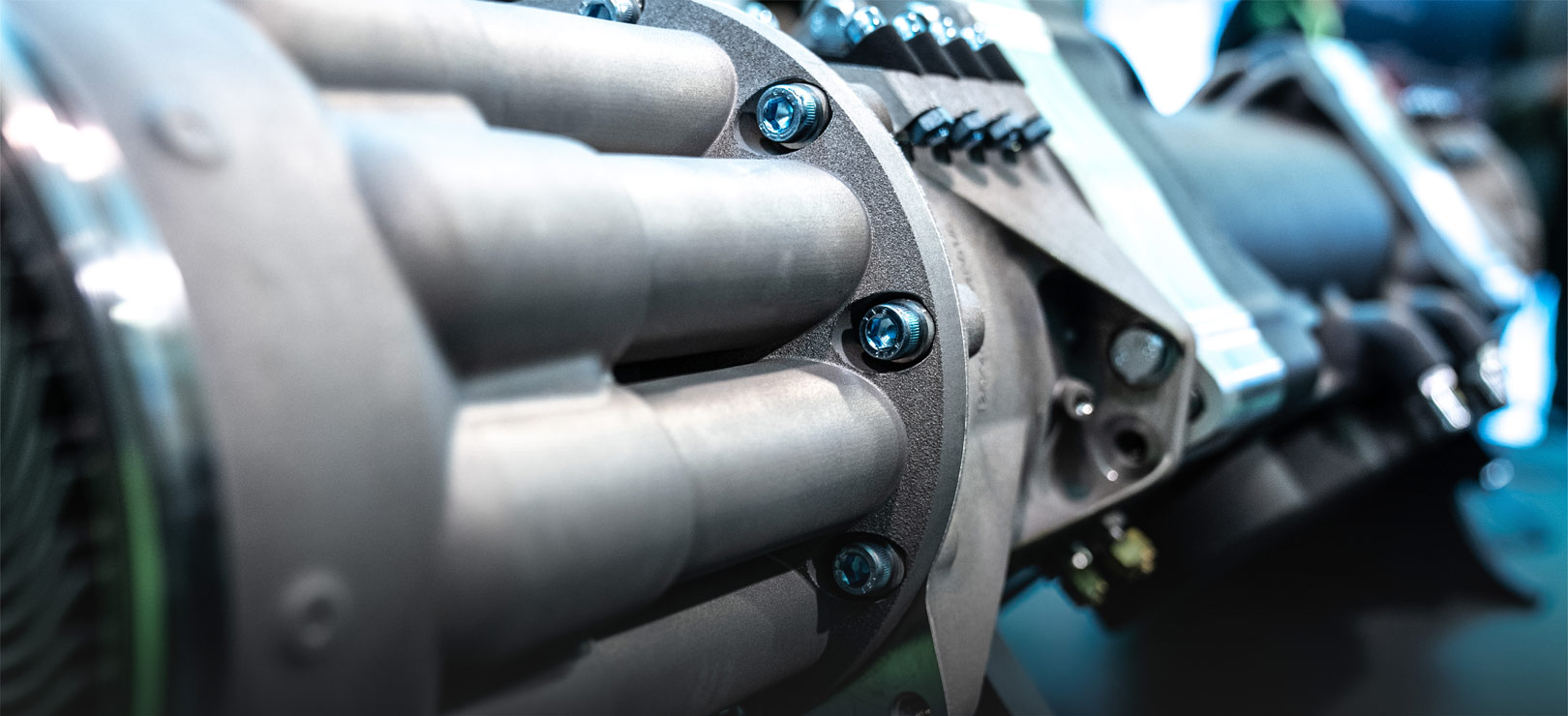

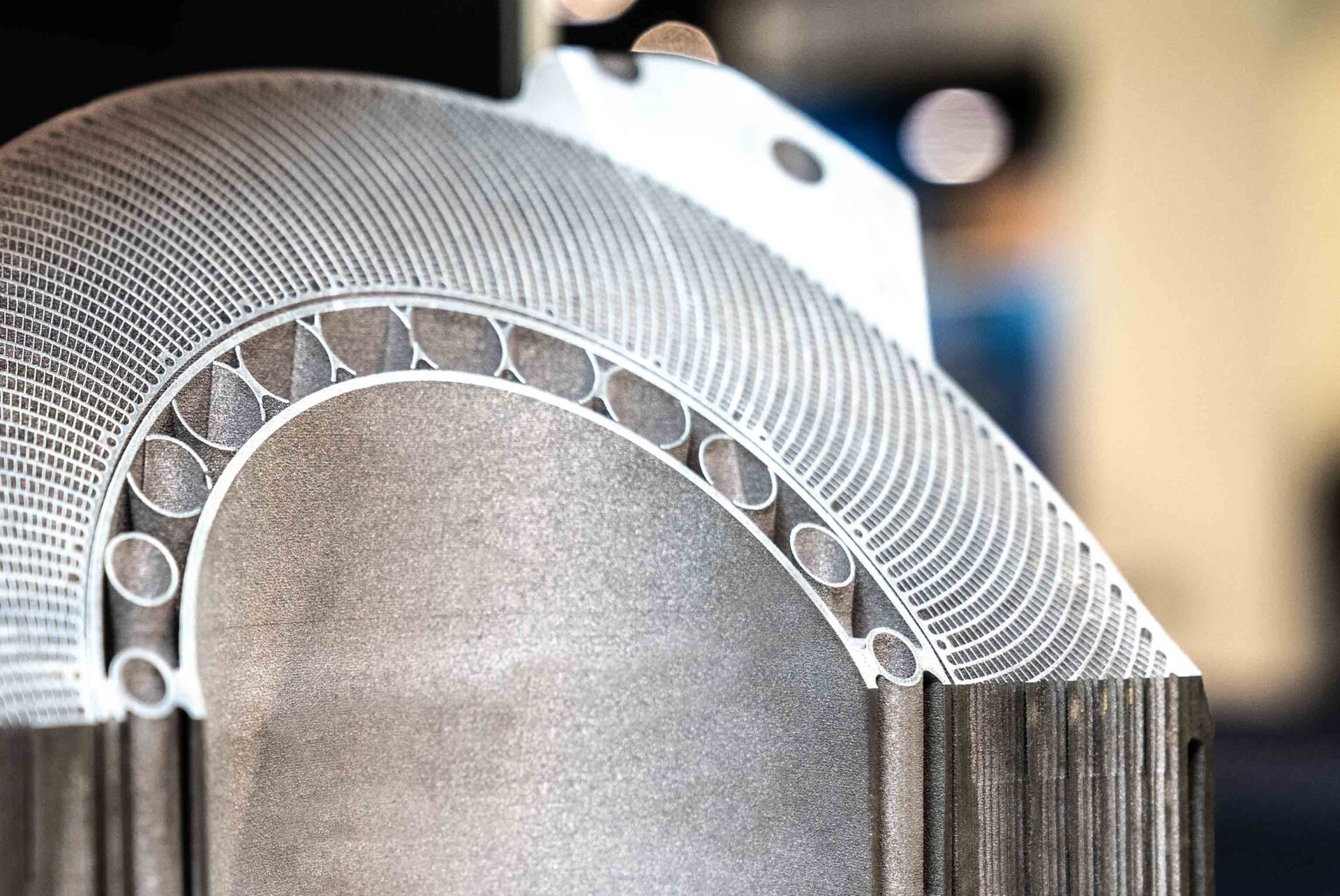

An additive manufacturing enabled generator technology that uses heat to drive a sealed electricity producing linear generator

How it Works

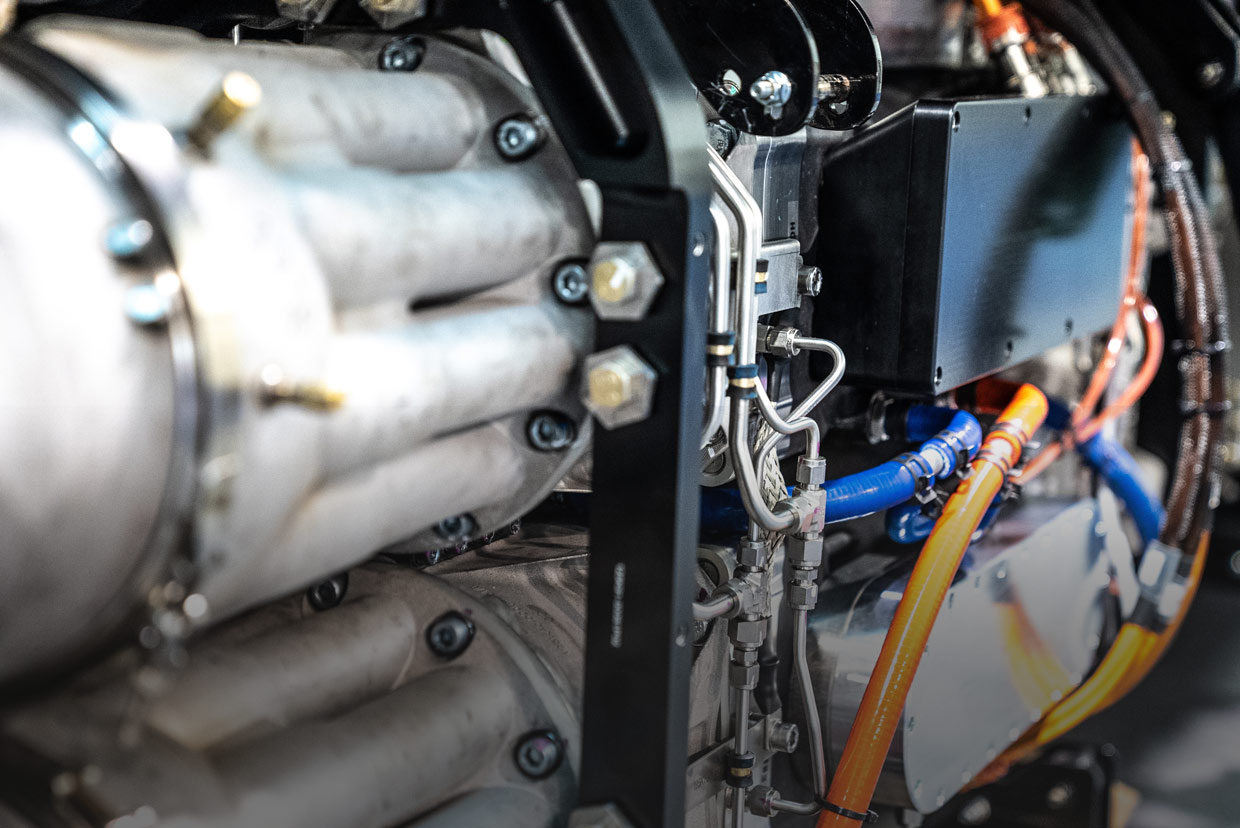

Similar to a linear free-piston Stirling Cycle, the KARNO generator uses heat to expand working fluid within a hermetically sealed cavity, pushing a piston assembly through a magnetic field to create electric current. This heat can be created by reacting fuels in an external reaction chamber or captured from other external heat sources.

Unlock the true potential of stationary power applications with KARNO, the game-changing generator technology. From enabling EV charging and renewable matching to peak shaving, providing prime power, and waste gas utilization, KARNO generator technology empowers operators with increased efficiency and reliability, revolutionizing the way energy is harnessed for a sustainable future.

Learn more about clean, flexible and affordable electricity production.

Get in Touch