- Home

- Innovations

Power Your Future

with Hyliion® Technology

At Hyliion, we view innovation as core to our mission of being a leading provider of innovative solutions for an ever changing energy economy. Our approach to innovation doesn’t start with our products, it starts with our customers and the end-user. By seeking to understand and solve their pain points, we can put our innovation to work.

Hyliion’s Insights

Innovation with a Purpose

Technology for the sake of technology doesn’t solve the problem, it just makes it more expensive. We focus on truly solving the problems facing our industry, which sometimes means taking a different path than others. It also means moving with speed and agility to bring solutions to market, to solve the problem now, and not five years from now.

Making Innovation Count

It is good to create solutions that benefit the environment. It is even better to create solutions that benefit the environment and actual human needs. We choose the latter, because if people don’t see the benefit of adopting a solution, the environment certainly never will.

Reduce Emissions

Improving the emissions profile of our customers is at the core of everything we do

Reduce Costs

By focusing on solutions that improve operating costs, we also help with the bottom line as well

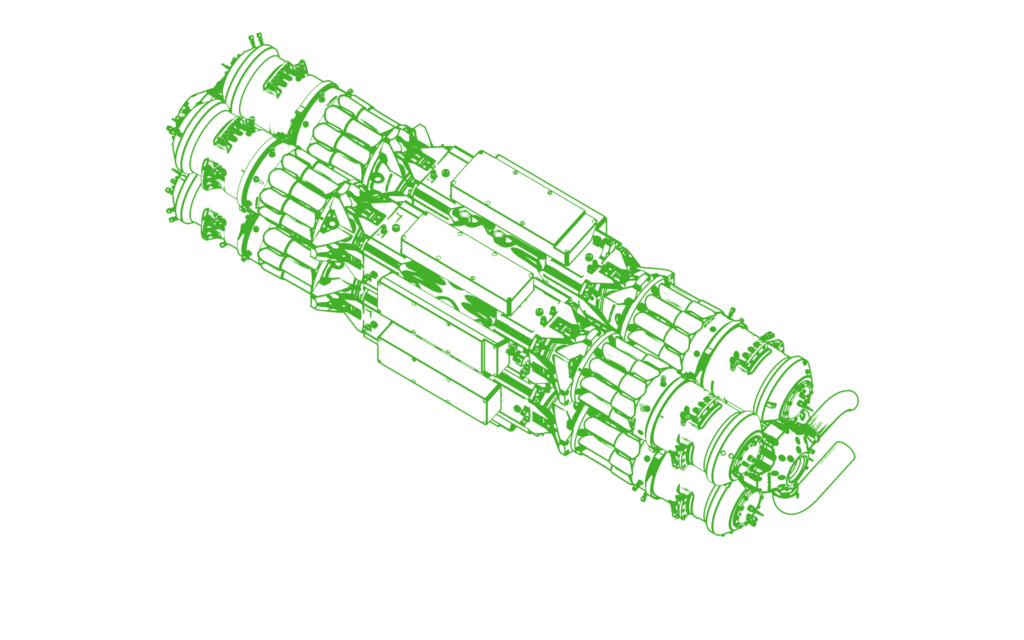

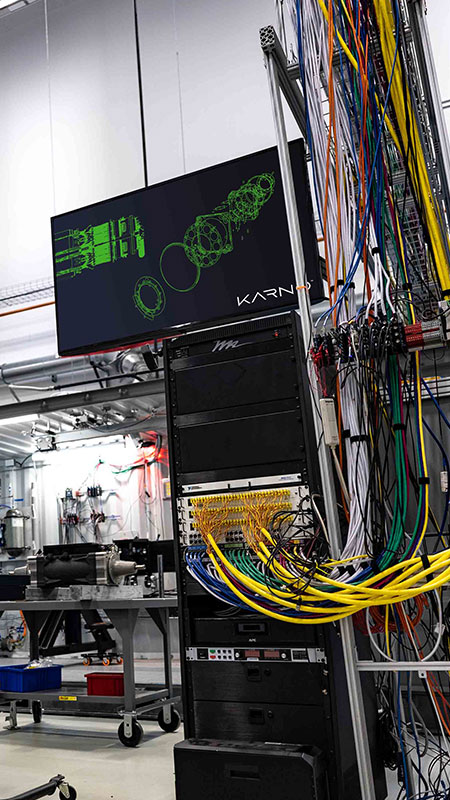

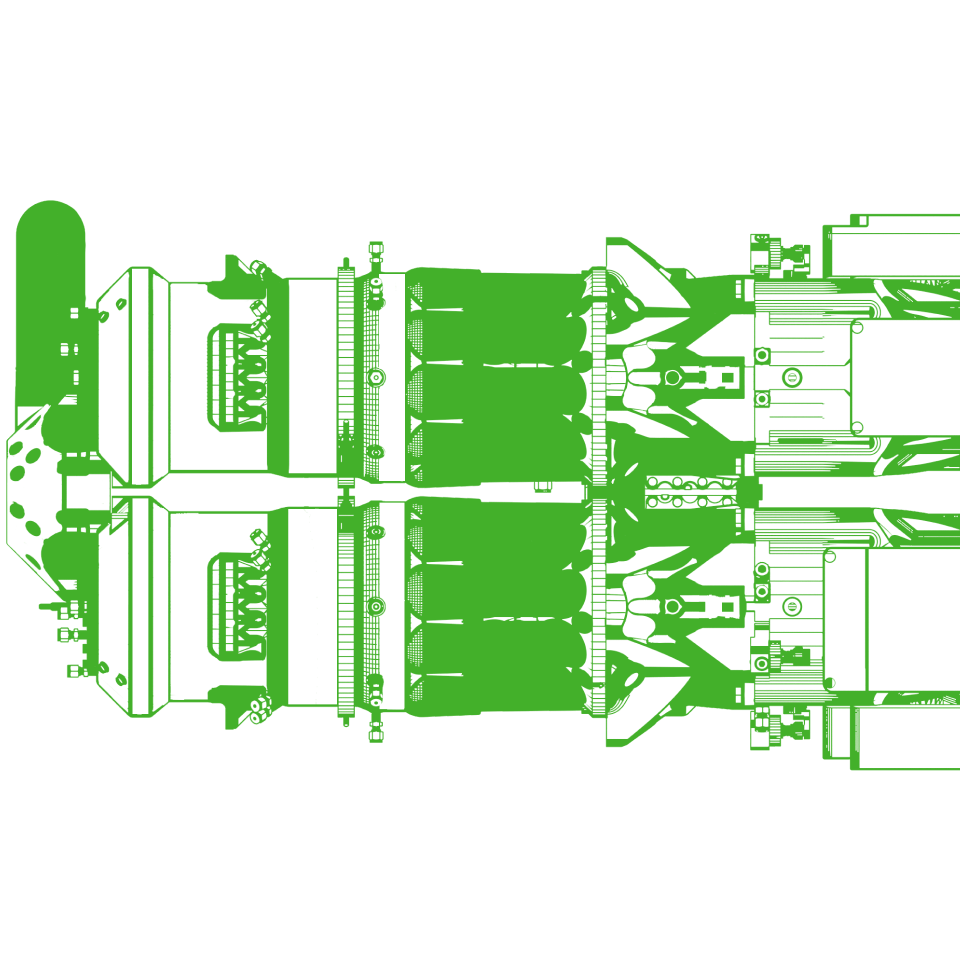

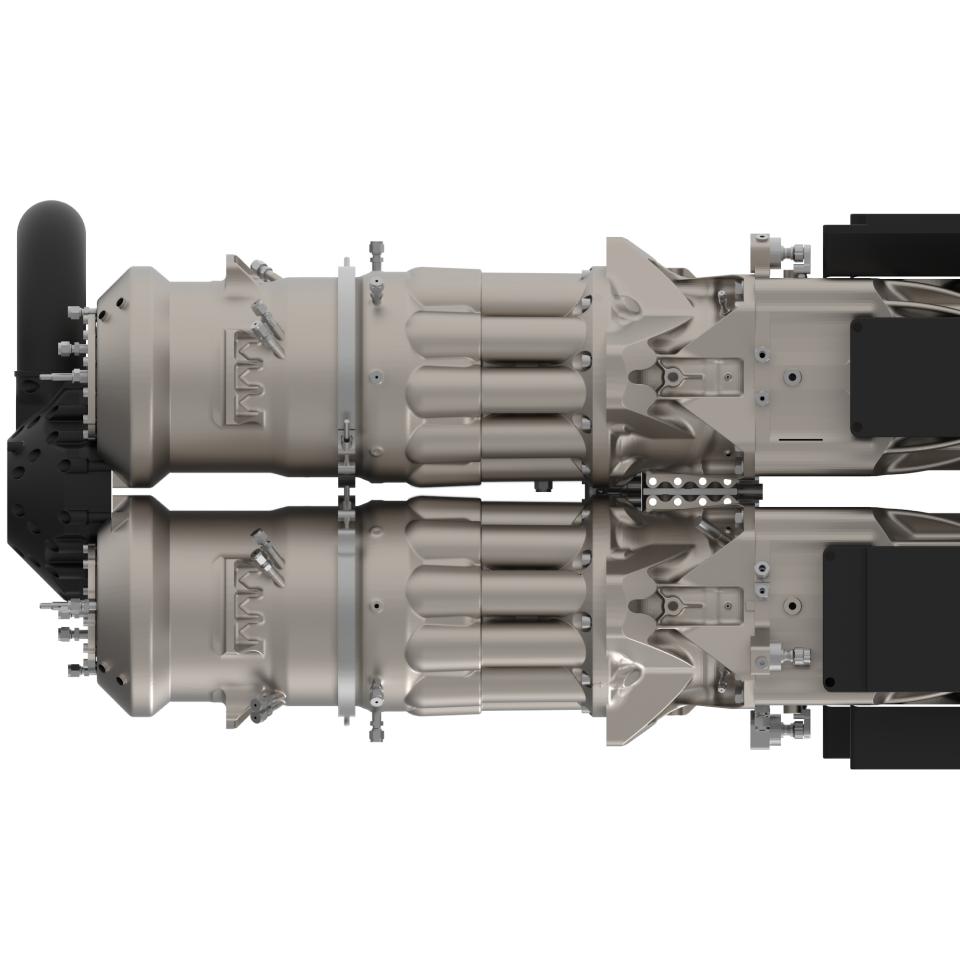

KARNO™ Generator

The additive manufacturing enabled KARNO generator uses heat produced in an external reaction chamber to drive a sealed linear generator to produce electricity. That heat is produced by reacting one of over 20 compatible fuels through flameless oxidation. This unique generator technology can be used in multiple different applications from prime power to peak shaving and renewables matching. As a result of its novel design, it reduces emissions and maintenance, and improves efficiency, when compared with a traditional internal combustion engine.

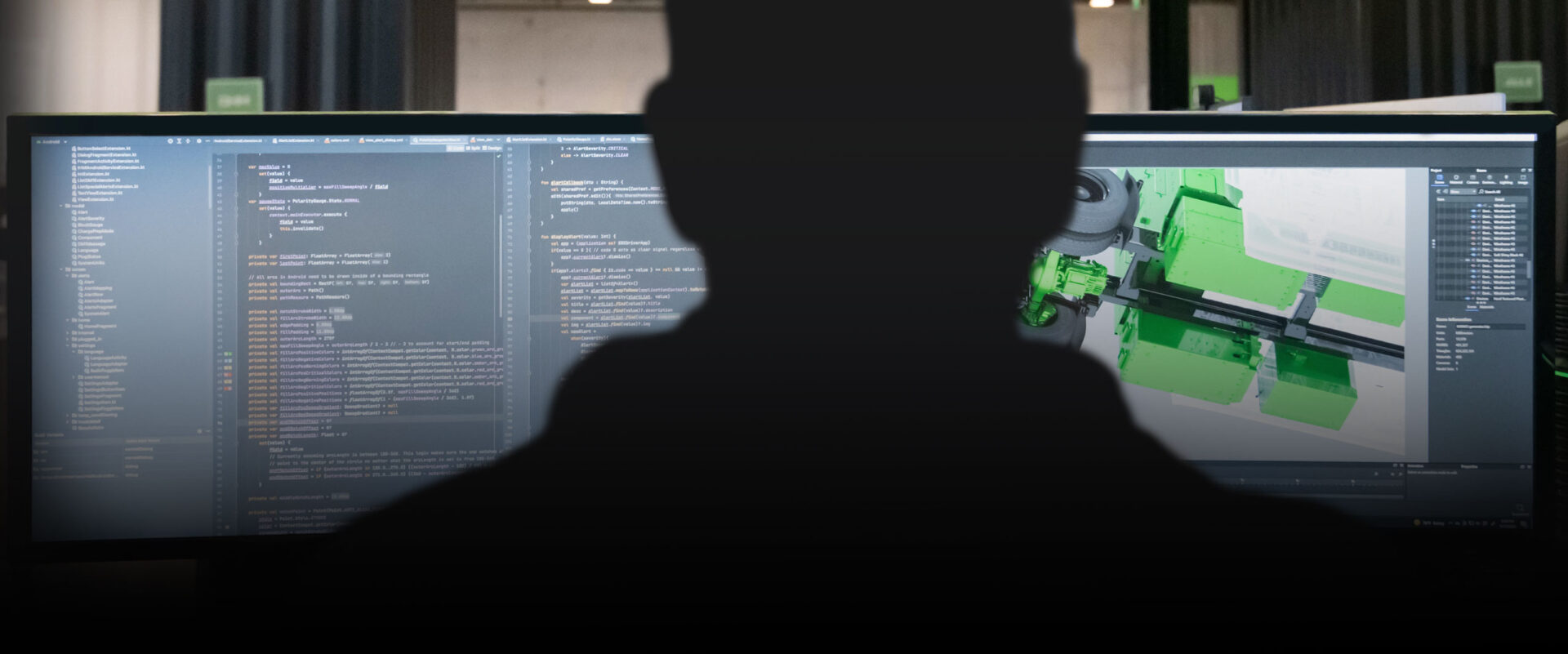

Software

Software is at the core of what we do at Hyliion. In a generator or in the cloud, we utilize software to add value to the customer and user experience.

Learn more about clean, flexible and affordable electricity production.

Get in Touch